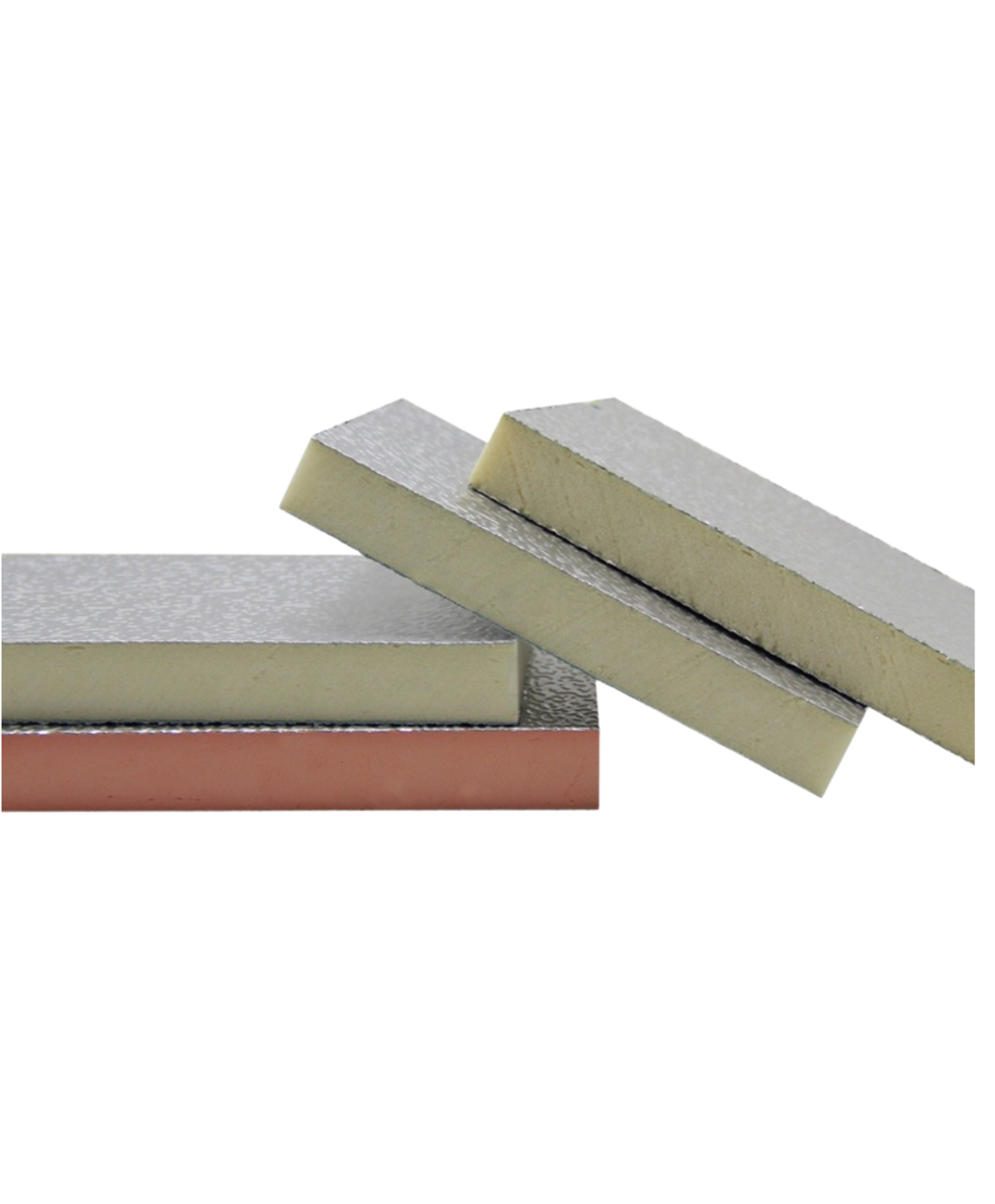

PIR Sheet 20MM Regular & Fire Rated

PIR Sheet 20MM Regular & Fire Rated

Related Products

NBR-Single Sided Foam Tape

NBR-Single Sided Foam TapeDiamond Aluminum Foil Tape is made up of an aluminum foil backing, a high-performance adhesive, and an easy-release silicone paper liner.

Diamond Aluminum Foil Tape comes in three varieties: Hot Melt-based, Solvent-based, and FR Grade.

|

Properties |

Unit |

Solvent-based |

Hot Melt |

Premium Grade Solvent-Based |

FR Grade |

Test Method |

|

Backing Thickness |

microns |

20 ± 2 |

20 ± 2 |

40 ± 5 |

30 ± 5 |

ASTM – D3652 |

|

Total Thickness |

microns |

42 ± 2 |

45 ± 5 |

75 ± 5 |

70 ± 5 |

ASTM – D3652 |

|

Adhesion To Steel |

g/inch |

≥1300 |

≥1800 |

≥1700 |

≥1500 |

ASTM – D3330 |

|

Tensile Strength |

N/in² |

≥ 1500 |

≥ 1700 |

≥ 9800 |

≥ 1700 |

ASTM – D3759 |

|

Elongation at Break |

% |

≥ 2 |

≥ 2 |

≥ 10 |

≥ 5 |

ASTM – D3759 |

|

Shear Test |

hours |

≥ 96 |

≥ 96 |

≥ 96 |

≥ 96 |

ASTM – D3654 |

|

Roll Ball Tack |

mm |

≤ 120 |

≤ 100 |

≤ 120 |

≤ 120 |

ASTM – D3121 |

|

Temperature Range |

˚C |

-20 to +80 |

-5 to +65 |

-20 to +80 |

-30 to +120 |

– |

|

Fire Rating |

NA |

– |

– |

– |

Class 0 |

BS 476 Part 6 & 7 |

|

Product |

Backing |

Adhesive |

Color |

Release Paper |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

Hot Melt-based |

Soft Tempered Aluminum Foil 8011 |

Hot Melt PSA |

Shiny Silver |

White |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

FR Grade |

FR Grade Class 0 Aluminum Foil |

Flame Retardant |

Shiny Silver |

White |

|

Standard Sizes |

||

|

Width (mm) |

Length (yd) |

Rolls / Box |

|

48 |

25 / 30 |

24 |

|

72 |

25 / 30 |

16 |

|

96 |

25 / 30

|

12 |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water, and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging.

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variation. Users are to determine the suitability of the product for its intended purpose.

Delta-flex Flexible Duct

Delta-flex Flexible DuctDelta-flex Flexible Duct is a very strong fully flexible compressible light weight air duct which is widely used in Air Conditioning and Ventilation Systems for Commercial, Industrial and Residential applications. Delta-flex is extremely durable and will maintain dimensional stability when fully extended.

Delta-flex Flexible Duct is UL listed flexible duct according to UL 181 Class 1 standard. Also classified by Underwriters Laboratories INC, in accordance with ADC flexible duct performance and installation standards using ASTM C518. Delta-flex Flexible Duct has tested as per ASTM E84.

Applications:

- Delta-flex Flexible Duct complies with UAE Fire & Life Safety Code – 2018.

- The insulation is DCL certified.

- The insulation confirms with Dubai Green Building Code.

- Diameter: 4” to 20”

- Insulation Density: (16, 24, 32) kg/m3

- Available Insulation Thickness: 25 mm

- Length: 25 feet

- Maximum Velocity: 5000 FPM (25.5 m/s)

- Maximum Positive Pressure: 10” W.C. (2.5 KPa)

- Maximum Negative Pressure: ½” W.C. (0.12 KPa)

- Insulation R Value: 4.2 or 6 (F-hr/BTU)

Delta-flex Semi Rigid Flexible Duct

Delta-flex Semi Rigid Flexible Duct

Hurry Up!

Offer ends in:

Delta-flex Semi Rigid Flexible Duct

Delta-flex Semi Rigid Flexible DuctDelta-flex Semi-Rigid Flexible Duct complies with UL 181 Class 0 standard having surface burning characteristic zero (i.e. flame spread and smoke-developed). Delta-flex is manufactured in accordance with (NFPA 90A & 90B standards).

Fire-resistant, non-combustible, lightweight, very strong with a high degree of flexibility, which is widely used in dryer, bathroom, or kitchen ventilation for commercial, industrial and residential applications.

Available in Insulated & Uninsulated types.

- Available ID: 3” to 14”

- Standard Length: 10 feet

Delta Duct Flanging System

Delta Duct Flanging System- Delta flanges are the easier and faster way to connect the transverse joint of rectangular ducts.

- Permanently flexible non-drying, non-toxic sealant injected into the profile during the manufacturing process.

- Available in 20 mm, 30 mm and 40 mm.

Design Specification: All galvanized steel sheet ductworks shall be transverse jointed with proprietary factory fabricated slide on duct flange system including 20, 30 & 40 size duct flange, with matching corner, cleats and clamps.

Delta-flex Flexible Duct Connector

Delta-flex Flexible Duct Connector

Hurry Up!

Offer ends in:

N Clad Tape

N Clad TapeDiamond Aluminum Foil Tape is made up of an aluminum foil backing, a high-performance adhesive, and an easy-release silicone paper liner.

Diamond Aluminum Foil Tape comes in three varieties: Hot Melt-based, Solvent-based, and FR Grade.

|

Properties |

Unit |

Solvent-based |

Hot Melt |

Premium Grade Solvent-Based |

FR Grade |

Test Method |

|

Backing Thickness |

microns |

20 ± 2 |

20 ± 2 |

40 ± 5 |

30 ± 5 |

ASTM – D3652 |

|

Total Thickness |

microns |

42 ± 2 |

45 ± 5 |

75 ± 5 |

70 ± 5 |

ASTM – D3652 |

|

Adhesion To Steel |

g/inch |

≥1300 |

≥1800 |

≥1700 |

≥1500 |

ASTM – D3330 |

|

Tensile Strength |

N/in² |

≥ 1500 |

≥ 1700 |

≥ 9800 |

≥ 1700 |

ASTM – D3759 |

|

Elongation at Break |

% |

≥ 2 |

≥ 2 |

≥ 10 |

≥ 5 |

ASTM – D3759 |

|

Shear Test |

hours |

≥ 96 |

≥ 96 |

≥ 96 |

≥ 96 |

ASTM – D3654 |

|

Roll Ball Tack |

mm |

≤ 120 |

≤ 100 |

≤ 120 |

≤ 120 |

ASTM – D3121 |

|

Temperature Range |

˚C |

-20 to +80 |

-5 to +65 |

-20 to +80 |

-30 to +120 |

– |

|

Fire Rating |

NA |

– |

– |

– |

Class 0 |

BS 476 Part 6 & 7 |

|

Product |

Backing |

Adhesive |

Color |

Release Paper |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

Hot Melt-based |

Soft Tempered Aluminum Foil 8011 |

Hot Melt PSA |

Shiny Silver |

White |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

FR Grade |

FR Grade Class 0 Aluminum Foil |

Flame Retardant |

Shiny Silver |

White |

|

Standard Sizes |

||

|

Width (mm) |

Length (yd) |

Rolls / Box |

|

48 |

25 / 30 |

24 |

|

72 |

25 / 30 |

16 |

|

96 |

25 / 30

|

12 |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water, and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging.

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variation. Users are to determine the suitability of the product for its intended purpose.

Reviews

There are no reviews yet.