Delta Pins

Delta Pins

Delta pins are designed to fix insulating materials to smooth surfaces such as air ducts, attenuators, chambers, and enclosures. Also known as Stuck-up pins, their use allows proper and speedy quality fixtures without the risk of corrosion.

Related Products

Delta Duct Adhesive

Delta Duct AdhesiveDelta Duct RG 242 is inflammable, heat resistant, and one component adhesive. It is specially developed for rubber, resin etc.

Delta Duct RG 242 has correct balance of wet and dry tack with smooth flow properties and uniform and fast drying characteristics. Delta Duct RG 242 is having very good heat properties.

Delta Duct RG 242 has excellent adhesion and good compatibility on Nitrile Rubber, PU Rubber, Fiber Glass, Steel, Wood, Concrete etc.

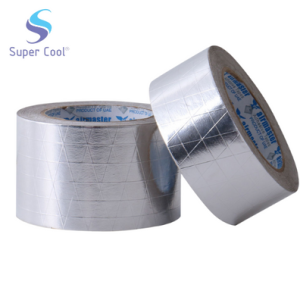

NBR-Single Sided Foam Tape

NBR-Single Sided Foam TapeDiamond Aluminum Foil Tape is made up of an aluminum foil backing, a high-performance adhesive, and an easy-release silicone paper liner.

Diamond Aluminum Foil Tape comes in three varieties: Hot Melt-based, Solvent-based, and FR Grade.

|

Properties |

Unit |

Solvent-based |

Hot Melt |

Premium Grade Solvent-Based |

FR Grade |

Test Method |

|

Backing Thickness |

microns |

20 ± 2 |

20 ± 2 |

40 ± 5 |

30 ± 5 |

ASTM – D3652 |

|

Total Thickness |

microns |

42 ± 2 |

45 ± 5 |

75 ± 5 |

70 ± 5 |

ASTM – D3652 |

|

Adhesion To Steel |

g/inch |

≥1300 |

≥1800 |

≥1700 |

≥1500 |

ASTM – D3330 |

|

Tensile Strength |

N/in² |

≥ 1500 |

≥ 1700 |

≥ 9800 |

≥ 1700 |

ASTM – D3759 |

|

Elongation at Break |

% |

≥ 2 |

≥ 2 |

≥ 10 |

≥ 5 |

ASTM – D3759 |

|

Shear Test |

hours |

≥ 96 |

≥ 96 |

≥ 96 |

≥ 96 |

ASTM – D3654 |

|

Roll Ball Tack |

mm |

≤ 120 |

≤ 100 |

≤ 120 |

≤ 120 |

ASTM – D3121 |

|

Temperature Range |

˚C |

-20 to +80 |

-5 to +65 |

-20 to +80 |

-30 to +120 |

– |

|

Fire Rating |

NA |

– |

– |

– |

Class 0 |

BS 476 Part 6 & 7 |

|

Product |

Backing |

Adhesive |

Color |

Release Paper |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

Hot Melt-based |

Soft Tempered Aluminum Foil 8011 |

Hot Melt PSA |

Shiny Silver |

White |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

FR Grade |

FR Grade Class 0 Aluminum Foil |

Flame Retardant |

Shiny Silver |

White |

|

Standard Sizes |

||

|

Width (mm) |

Length (yd) |

Rolls / Box |

|

48 |

25 / 30 |

24 |

|

72 |

25 / 30 |

16 |

|

96 |

25 / 30

|

12 |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water, and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging.

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variation. Users are to determine the suitability of the product for its intended purpose.

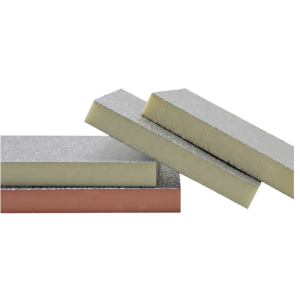

PIR Sheet 20MM Regular & Fire Rated

PIR Sheet 20MM Regular & Fire Rated

Hurry Up!

Offer ends in:

Delta-flex Semi Rigid Flexible Duct

Delta-flex Semi Rigid Flexible Duct

Hurry Up!

Offer ends in:

Delta-flex Semi Rigid Flexible Duct

Delta-flex Semi Rigid Flexible DuctDelta-flex Semi-Rigid Flexible Duct complies with UL 181 Class 0 standard having surface burning characteristic zero (i.e. flame spread and smoke-developed). Delta-flex is manufactured in accordance with (NFPA 90A & 90B standards).

Fire-resistant, non-combustible, lightweight, very strong with a high degree of flexibility, which is widely used in dryer, bathroom, or kitchen ventilation for commercial, industrial and residential applications.

Available in Insulated & Uninsulated types.

- Available ID: 3” to 14”

- Standard Length: 10 feet

Aluglass Tape

Aluglass TapeDiamond Aluminum Foil Tape is made up of an aluminum foil backing, a high-performance adhesive, and an easy-release silicone paper liner.

Diamond Aluminum Foil Tape comes in three varieties: Hot Melt-based, Solvent-based, and FR Grade.

|

Properties |

Unit |

Solvent-based |

Hot Melt |

Premium Grade Solvent-Based |

FR Grade |

Test Method |

|

Backing Thickness |

microns |

20 ± 2 |

20 ± 2 |

40 ± 5 |

30 ± 5 |

ASTM – D3652 |

|

Total Thickness |

microns |

42 ± 2 |

45 ± 5 |

75 ± 5 |

70 ± 5 |

ASTM – D3652 |

|

Adhesion To Steel |

g/inch |

≥1300 |

≥1800 |

≥1700 |

≥1500 |

ASTM – D3330 |

|

Tensile Strength |

N/in² |

≥ 1500 |

≥ 1700 |

≥ 9800 |

≥ 1700 |

ASTM – D3759 |

|

Elongation at Break |

% |

≥ 2 |

≥ 2 |

≥ 10 |

≥ 5 |

ASTM – D3759 |

|

Shear Test |

hours |

≥ 96 |

≥ 96 |

≥ 96 |

≥ 96 |

ASTM – D3654 |

|

Roll Ball Tack |

mm |

≤ 120 |

≤ 100 |

≤ 120 |

≤ 120 |

ASTM – D3121 |

|

Temperature Range |

˚C |

-20 to +80 |

-5 to +65 |

-20 to +80 |

-30 to +120 |

– |

|

Fire Rating |

NA |

– |

– |

– |

Class 0 |

BS 476 Part 6 & 7 |

|

Product |

Backing |

Adhesive |

Color |

Release Paper |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

Hot Melt-based |

Soft Tempered Aluminum Foil 8011 |

Hot Melt PSA |

Shiny Silver |

White |

|

Solvent-based |

Soft Tempered Aluminum Foil 8011 |

Solvent Acrylic |

Shiny Silver |

White |

|

FR Grade |

FR Grade Class 0 Aluminum Foil |

Flame Retardant |

Shiny Silver |

White |

|

Standard Sizes |

||

|

Width (mm) |

Length (yd) |

Rolls / Box |

|

48 |

25 / 30 |

24 |

|

72 |

25 / 30 |

16 |

|

96 |

25 / 30

|

12 |

Application Instructions:

Before applying, the surface must be free from oil, solvent, water, and dust. For best product performance, apply the tape at room temperature between 15°C and 35°C.

Storage:

Store under normal room temperature and 50% RH in the original packaging.

Product Expiry:

Use within 12 months from the date of manufacturing.

Note: The values provided above are results of standard lab tests and are subject to variation. Users are to determine the suitability of the product for its intended purpose.

PIR Sheet 20MM Regular & Fire Rated

PIR Sheet 20MM Regular & Fire Rated

Hurry Up!

Offer ends in:

Reviews

There are no reviews yet.