R410 Switch Connector

R410 Switch Connector

Related Products

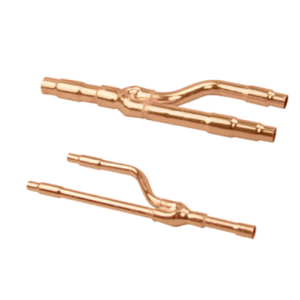

Daikin Copper Branching Joint

Daikin Copper Branching JointDaikin Copper Branching Joint

They are always used in central air conditioner system,used as branch joint for refrigerating pipes.They are composed by copper accessories, for VRF air conditioner refrigerant piping systems (multi split with Variable Refrigerant Flow, especially in R410a system) in different forms. We warrant quality of our products thanks to our experience in the refrigerating sector.

Daikin Copper Distribution Tube Fittings:

Daikin-DJ-11T

Daikin-DJ-18T

Daikin-DJ-37T

Daikin-DJ-40T

Daikin-DJ-75T

Daikin-DJ-76T

Daikin-DJ-90T(for outdoor unit)

Daikin-DJ-135T(for outdoor unit)

Daikin R410A Copper Distribution Tube Fittings :

Daikin-DJX-22T

Daikin-DJX-33T

Daikin-DJX-72T

Daikin-DJX-73T

Daikin-DJX-73TP

Daikin-DJX-C90(for outdoor unit)

Daikin-DJX-C135(for outdoor unit)

Copper Branching Joint for Twin Air Conditioner System

Copper Branching Joint for Twin Air Conditioner System

Hurry Up!

Offer ends in:

Copper Branching Joint for Twin Air Conditioner System

Copper Branching Joint for Twin Air Conditioner System1/4″ Maksal Copper Coil – OD 6.35mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

1/4″ Maksal Copper Coil – OD 6.35mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

Hurry Up!

Offer ends in:

1/4″ Maksal Copper Coil – OD 6.35mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

1/4″ Maksal Copper Coil – OD 6.35mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard| ASTM B280 SOFT ANNEALED COILS | ||||||

| Manufacture Size | Mass Per m/kg |

|||||

| mm | Inches | |||||

| OD | WT | OD | WT | |||

| 6.35 | 0.76 | 1/4″ | 0.030 | 0.119 | ||

| Application: | Used in supermarkets, cold rooms, display fridges & air conditioners for the connection, repairs, or alteration of air conditioning of refrigeration units in the field or under construction. | |||||

| Quality: | Maksal ACR tubing is manufactured to consistently meet the demands of the industry and is compatible with all refrigerants. | |||||

| Cleanliness: | Bore quality meets the 0.038 g/m2 ASTM B280 specified limit. | |||||

| Material: | C12200, Cu 99.9%min, P 0.015 – 0.040% | |||||

| Mechanical Properties: | Tensile Strength 205 MPa / min Yield Stress 8 MPa Elongation min 3% Hardness > 40 – 50 VPN Soft Annealed |

|||||

| Joining: | Suitably connected by means of capillary solder fittings. | |||||

| Bending: | Suitable for bending with or without specialized tooling. | |||||

| Length: | 50ft or 15.24m | |||||

1/8″ Maksal Copper Coil – OD 3.18mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

1/8″ Maksal Copper Coil – OD 3.18mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

Hurry Up!

Offer ends in:

1/8″ Maksal Copper Coil – OD 3.18mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard

1/8″ Maksal Copper Coil – OD 3.18mm WT 0.76mm – 50ft 15.24 Meter Coils – Standard| ASTM B280 SOFT ANNEALED COILS | ||||||

| Manufacture Size | Mass Per m/kg |

|||||

| mm | Inches | |||||

| OD | WT | OD | WT | |||

| 3.18 | 0.76 | 1/8″ | 0.030 | 0.051 | ||

| Application: | Used in supermarkets, cold rooms, display fridges & air conditioners for the

connection, repairs, or alteration of air conditioning of refrigeration units in the field or under construction. |

|||||

| Quality: | Maksal ACR tubing is manufactured to consistently meet the demands of the industry and is compatible with all refrigerants. | |||||

| Cleanliness: | Bore quality meets the 0.038 g/m2 ASTM B280 specified limit. | |||||

| Material: | C12200, Cu 99.9%min, P 0.015 – 0.040% | |||||

| Mechanical Properties: | Tensile Strength 205 MPa / min Yield Stress 8 MPa Elongation min 3% Hardness > 40 – 50 VPN Soft Annealed |

|||||

| Joining: | Suitably connected by means of capillary solder fittings. | |||||

| Bending: | Suitable for bending with or without specialized tooling. | |||||

| Length: | 50ft or 15.24m | |||||

1 1/8″ Maksal Copper Coil – OD 28.58mm WT 1.27mm – 50ft 15.24 Meter Coils – Standard

1 1/8″ Maksal Copper Coil – OD 28.58mm WT 1.27mm – 50ft 15.24 Meter Coils – Standard

Hurry Up!

Offer ends in:

1 1/8″ Maksal Copper Coil – OD 28.58mm WT 1.27mm – 50ft 15.24 Meter Coils – Standard

1 1/8″ Maksal Copper Coil – OD 28.58mm WT 1.27mm – 50ft 15.24 Meter Coils – Standard| ASTM B280 SOFT ANNEALED COILS | ||||||

| Manufacture Size | Mass Per m/kg |

|||||

| mm | Inches | |||||

| OD | WT | OD | WT | |||

| 28.58 | 1.27 | 1 1/8″ | 0.050 | 0.971 | ||

| Application: | Used in supermarkets, cold rooms, display fridges & air conditioners for the connection, repairs, or alteration of air conditioning of refrigeration units in the field or under construction. | |||||

| Quality: | Maksal ACR tubing is manufactured to consistently meet the demands of the industry and is compatible with all refrigerants. | |||||

| Cleanliness: | Bore quality meets the 0.038 g/m2 ASTM B280 specified limit. | |||||

| Material: | C12200, Cu 99.9%min, P 0.015 – 0.040% | |||||

| Mechanical Properties: | Tensile Strength 205 MPa / min Yield Stress 8 MPa Elongation min 3% Hardness > 40 – 50 VPN Soft Annealed |

|||||

| Temper: | Soft Annealed. | |||||

| Packaging: | End capped, double layer coiled and shrink wrapped. | |||||

| Joining: | Suitably connected by means of capillary solder fittings. | |||||

| Bending: | Suitable for bending with or without specialized tooling. | |||||

| Length: | 50ft or 15.24m | |||||

1/2″ Maksal Copper Coil – OD 12.70mm WT 0.71mm – 50ft 15.24 Meter Coils – Economical

1/2″ Maksal Copper Coil – OD 12.70mm WT 0.71mm – 50ft 15.24 Meter Coils – Economical

Hurry Up!

Offer ends in:

1/2″ Maksal Copper Coil – OD 12.70mm WT 0.71mm – 50ft 15.24 Meter Coils – Economical

1/2″ Maksal Copper Coil – OD 12.70mm WT 0.71mm – 50ft 15.24 Meter Coils – Economical| SOFT UNNEALED COILS | |||||||||

| Manufacture Size | Mass per m/kg |

Mass per Coil |

Coils per Carton |

Maas per Carton |

|||||

| mm | Inches | ||||||||

| OD | WT | OD | WT | ||||||

| 12.70 | 0.71 | 1/2″ | 0.028 | 0.2384 | 3.633 | 5 | 18.163 | ||

| Application: | Used in supermarkets, cold rooms, display fridges & air conditioners for the

connection, repairs, or alteration of air conditioning of refrigeration units in the field or under construction. |

||||||||

| Quality: | Maksal ACR tubing is manufactured to consistently meet the demands of the

industry and is compatible with all refrigerants. |

||||||||

| Cleanliness: | Bore quality meets the 0.038 g/m2 ASTM B280 specified limit. | ||||||||

| Material: | C12200, Cu 99.9%min, P 0.015 – 0.040% | ||||||||

| Mechanical Properties: | Tensile Strength 205 MPa / min Yield Stress 8 MPa Elongation min 3% Hardness > 40 – 50 VPN Soft Annealed |

||||||||

| Joining: | Suitably connected by means of capillary solder fittings. | ||||||||

| Bending: | Suitable for bending with or without specialized tooling. | ||||||||

| Length: | 50ft or 15.24m | ||||||||

Reviews

There are no reviews yet.